您现在的位置是: 首页 - 白家电 - 辊制砂机的运作原理与应用实例 白家电

辊制砂机的运作原理与应用实例

2025-04-11 【白家电】 0人已围观

简介辊制砂机的基本结构与工作原理 辊制砂机是一种常见的机械设备,主要用于将大块石材或矿物转化为细小的颗粒。这种机器通常由两对相对移动的辊板组成,这两对辊板之间可以调节距离以适应不同尺寸和形状的大块材料。在辊板之间形成一个空间,当大块材料被推入这个空间时,由于辊板间隙较小,大块材料会受到压力和摩擦,最终被打碎成更细小的颗粒。 辊制砂机在建筑行业中的应用 在建筑工程中,特别是在混凝土生产过程中

辊制砂机的基本结构与工作原理

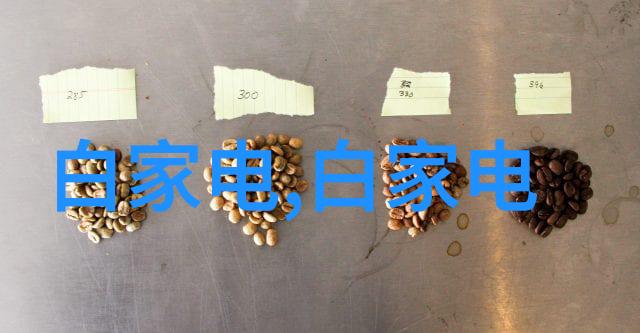

辊制砂机是一种常见的机械设备,主要用于将大块石材或矿物转化为细小的颗粒。这种机器通常由两对相对移动的辊板组成,这两对辊板之间可以调节距离以适应不同尺寸和形状的大块材料。在辊板之间形成一个空间,当大块材料被推入这个空间时,由于辊板间隙较小,大块材料会受到压力和摩擦,最终被打碎成更细小的颗粒。

辊制砂机在建筑行业中的应用

在建筑工程中,特别是在混凝土生产过程中,高质量的小颗粒是非常重要的。这些小颗粒不仅能提高混凝土强度,还能提供良好的流动性,使得混凝土能够更容易地填充复杂形状的地面和墙体结构。因此,1012型辊制砂机由于其高效、稳定且成本较低等特点,在建筑领域内广泛使用。

1012型�illis a type of crushing machine that is commonly used in the construction industry for producing high-quality sand and aggregate materials.

The machine features two pairs of counter-rotating rolls, which can be adjusted to accommodate different sizes and shapes of raw materials. When large blocks of material are fed into the gap between the rolls, they are subjected to pressure and friction, which causes them to break down into smaller particles.

Maintaining and repairing a 1012-type roller crusher

To ensure optimal performance and extend the lifespan of a 1012-type roller crusher, regular maintenance is essential. This includes daily checks on wear parts such as bearings, shafts, and rollers for signs of wear or damage. In addition, routine cleaning of dust accumulations from around moving parts helps prevent overheating issues caused by friction.

Factors affecting the efficiency of roller crushers like 1012

The efficiency of roller crushers like the 1012 model depends on several factors including feed size distribution, roll gap setting, roll surface condition (smoothness), speed ratio between rolls (if counter-rotating), moisture content in input material (which affects abrasion resistance) as well as hardness properties such as brittleness or ductility characteristics depending upon specific rock types being processed.

Advantages over other types crushing machines

Compared with jaw crushers or impactors when it comes to producing fine-grained aggregates with precise particle size distribution requirements for concrete production purposes,

Roller Crushers offer higher efficiencies due to less energy consumption during operation along with lower operating costs through reduced wear rates compared against these alternative technologies.

Moreover their compact design makes them suitable for use within confined spaces often found at job sites where space constraints exist.

7.

8.

9.

10.

11.

12.

13.

14.

15.