您现在的位置是: 首页 - 测评 - 疫苗生产的精密工作者空压机油水分离过滤器与工业离心机同心协作确保纯净度 测评

疫苗生产的精密工作者空压机油水分离过滤器与工业离心机同心协作确保纯净度

2025-01-24 【测评】 0人已围观

简介在疫苗生产的精细工序中,分离机扮演着至关重要的角色。预苗离心机,不仅是我们公司自主研发的一项新技术,而且它的设计和制造过程也充满了创新之举。首先,这款设备采用了微电脑控制系统,转速可以从0到16000次每分钟调节,这样的灵活性无疑为用户提供了更多的操作空间。在传统的离心机中,油脂润滑往往会污染物料,但我们的GQ105R高速管式离心机却不需要油脂润滑,这是因为它采用了一种国内独有的下阻尼技术

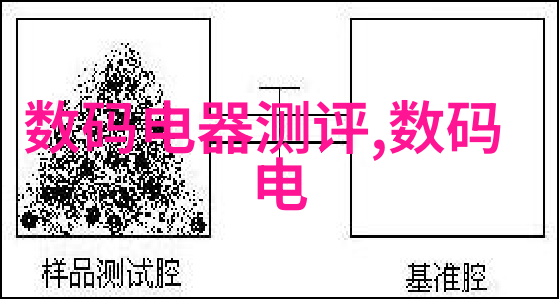

在疫苗生产的精细工序中,分离机扮演着至关重要的角色。预苗离心机,不仅是我们公司自主研发的一项新技术,而且它的设计和制造过程也充满了创新之举。首先,这款设备采用了微电脑控制系统,转速可以从0到16000次每分钟调节,这样的灵活性无疑为用户提供了更多的操作空间。在传统的离心机中,油脂润滑往往会污染物料,但我们的GQ105R高速管式离心机却不需要油脂润滑,这是因为它采用了一种国内独有的下阻尼技术。这意味着,我们能够彻底解决油脂污染的问题,使得整个生产过程更加纯净、安全。

此外,该设备的主要部件——包括机身和转鼓—all are made of stainless steel, ensuring not only its durability but also its ability to withstand the high standards of GMP (Good Manufacturing Practice). The machine's design is not only functional but also aesthetically pleasing, making it easy to clean and maintain. Its key features include a high speed range, large solid loading capacity, and a production capacity that can reach up to 1000 kilograms per hour.

The online sterilization centrifuge boasts an impressive separation factor of 15900 and can separate particles as small as 0.1 microns. It is particularly suitable for separating suspensions in biopharmaceuticals and vaccine production. To minimize frequent decantation, the suspension's solid content should not exceed 1%.

The GQ105R pipeline centrifuge has found wide applications in industries such as food-grade pharmaceuticals, vaccines preparation, traditional Chinese medicine preparations, plant protein extraction from fruits or vegetables, health foods and beverages where high-quality requirements are essential. It serves as equipment for processes involving antibiotic recovery or yeast recycling.

Our high-efficiency sterilization centrifuge offers detailed technical specifications including:

Drum rotational speed: 0-16000 r/min

Maximum g-force: up to 15800 RCF

Drum inner diameter: φ105mm

Drum effective length:742 mm

Solid volume inside drum:6 L

Material inlet pressure:>1.5 kg/cm²

Production capacity (water flow rate):0~1500 L/hour

Motor power:3 kw

This machine measures external dimensions at460×4948×1650 mm with inlet port diameter φ12 mm outlet port diameter φ38 mm weighing approximately520kg.

Model options include:

GQ-for liquid-solid separation; GF-for liquid-liquid-solid separation; W-for low-friction bearing system without oil lubrication; Z-for microcomputer control system.

Please note that actual production capacities may vary depending on material characteristics and separation requirements.

For users who need to separate materials under low temperatures,cold plates can be added upon request with cooling source provided by the user.

Customization options for all components coming into contact with materials include using316L stainless steel if required by clients.

In summary,a pre-vaccine centrifuge like ours plays a critical role in maintaining the purity of vaccines during their production process by efficiently separating various substances while adhering strictly to GMP guidelines.